Additive Manufacturing Techniques for Construction Industry

The development of additive manufacturing processes and the available materials have been driven by different application sectors. The construction industry is relatively a newer sector to adopt additive manufacturing solutions. Being a highly regulated industry, the construction sector requires large components with steel grades compatible with the existing ones used. Directed energy deposition (DED) processes may be the key to large parts with high productivity. But what is the influence of the process and the material combination on the final mechanical properties.

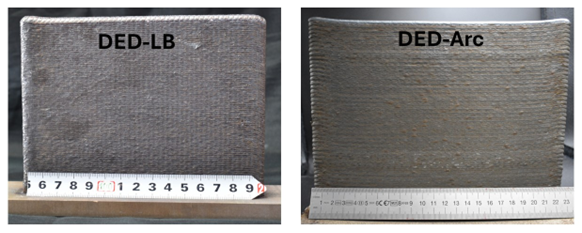

DED-Arc (Directed Energy Deposition-Arc) or wire arc additive manufacturing (WAAM) uses an electric arc to melt metal wire, building components layer by layer, while DED-LB (Directed Energy Deposition-Laser Beam) or laser metal deposition (LMD) utilizes a laser to melt metal powder or wire. DED-Arc tends to be faster, making it advantageous for larger deposition volumes, whereas DED-LB is often favoured for precision and intricate features due to its higher resolution. Both these methods can benefit from thorough quality inspection to enhance process output.

Through ConstructAdd, in collaboration with our partner BLM and Politecnico di Milano, we are working to benchmark these processes, evaluating their impact on mechanical behaviour, precision, and build rates using the same steel grade. The soon to be published results will constitute some of the first comparative analyses across different AM processes to be used in the construction industry.