ConstructAdd aims to place the Metal Additive Manufacturing in the mainstream of Architecture Engineering, Construction (AEC), and Automotive industries by developing rules and procedures for sustainable steel construction and electric vehicle applications.

Why?

Because, it is hard to meet European Green Deal objectives using the conventional materials and tools invented in previous centuries for the problems of the past.

Metal AM has the potential to be a game-changing solution, but:

• There are no specific Metal AM material and process rules for the AEC applications

• Only limited quantitative data are available on how Metal AM products compare to conventionally manufactured ones in terms of environmental impacts over their lifetime.

• There is not yet a model compatible for construction industry to confirm the environmental and economic feasibility of fabricating a #steel structure using Metal AM.

How?

By discovering these:

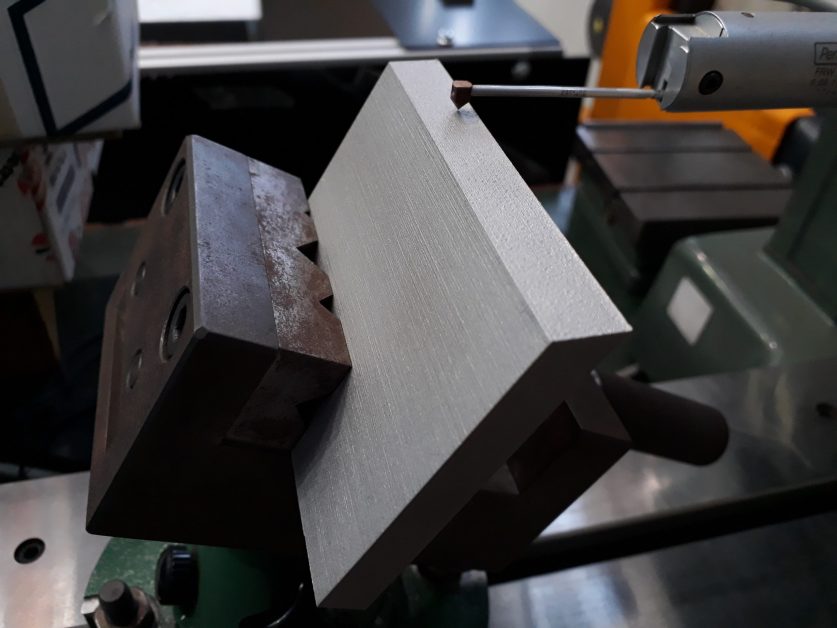

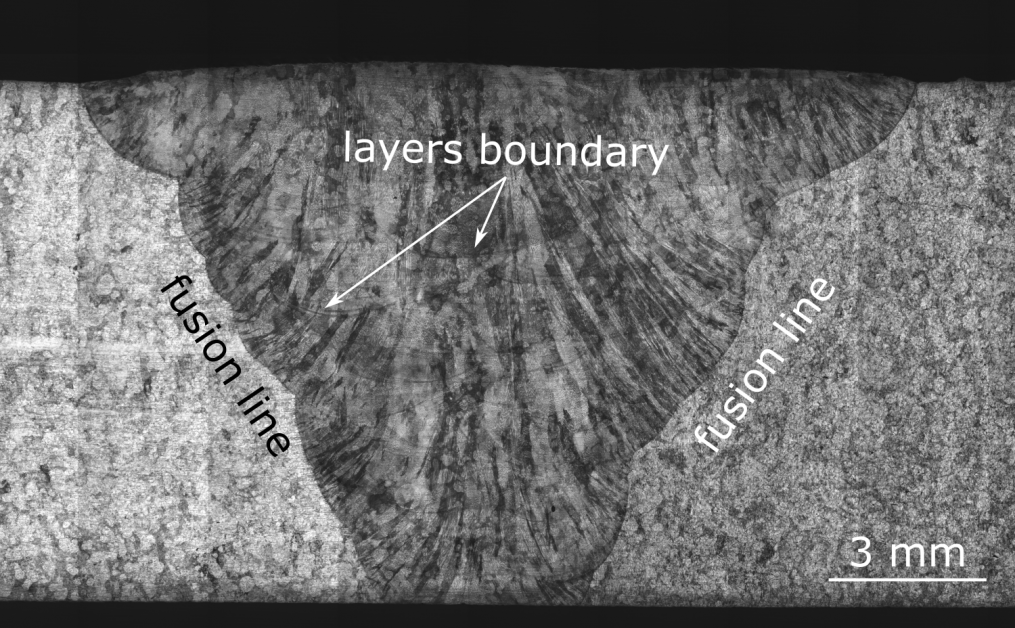

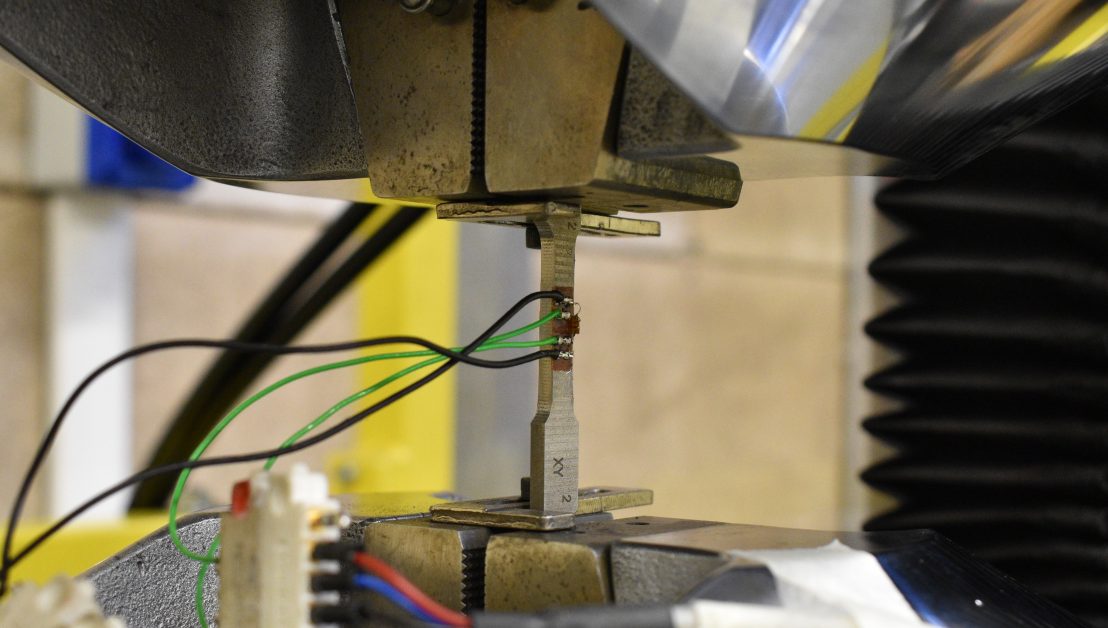

- Experimental performance of 3 Metal AM processes (LPBF, LDED, WAAM) with material and process parameters tailored to the AEC and Electric-vehicle component requirements

- Standardization route to comply with the EU #regulations, using the new experimental database of the printed metal and hybrid (3D printed + conventional) steel parts.

- Commercial/technical break-even points (in terms of cost and Life Cycle performance)